Mengapa Penting Memilih Bahan yang Tepat untuk Mold

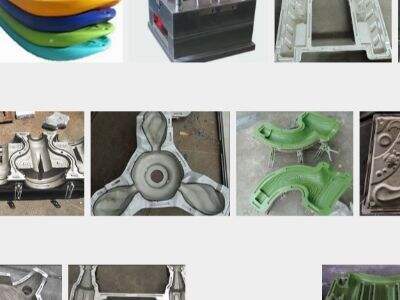

Ketika mempertimbangkan pemilihan mold rotomolding, Anda perlu memikirkan terlebih dahulu bahan yang akan Anda gunakan. Pilihan Anda akan secara langsung menentukan seberapa kuat, tahan lama, dan fleksibel produk akhir Anda. Sangat penting untuk memilih bahan yang tepat agar tidak retak, patah, atau melengkung selama proses rotomolding akibat panas dan tekanan. Bahan yang paling umum digunakan untuk mold rotomolding adalah aluminium, baja, dan kadang-kadang plastik, termasuk polietilen. Setiap bahan ini memiliki kelebihan dan kekurangan, jadi pastikan untuk mempertimbangkan Produk Rotomolding apa yang terbaik untuk proyek Anda.

Pengaruh Desain Mold terhadap Produk Akhir

Desain mold Anda sangat krusial, karena akan membentuk produk akhir Anda. Mold menentukan ukuran dan bentuk dari apa yang ingin Anda buat, itulah sebabnya Cetakan Aluminium Rotomolding sangat penting untuk memilih desain yang tepat untuk proyek Anda. Desain cetakan juga memengaruhi waktu yang dibutuhkan dan biaya untuk memproduksi produk Anda. Jadi jika Anda ingin membuat bentuk yang lebih kompleks atau rinci, akan membutuhkan waktu lebih lama dan persiapan lebih banyak untuk membuat cetakan tersebut. Ini berarti bahwa secara umum Anda akan mengeluarkan lebih banyak biaya untuk bahan dan produksi. Jadi selalu pertimbangkan dengan matang Produk Rotomolding ODM desainnya untuk memastikan itu memenuhi kebutuhan Anda!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

GA

GA

CY

CY

BE

BE

LA

LA

UZ

UZ